Grow your Company with the Heat Injector!

Powerful Performance

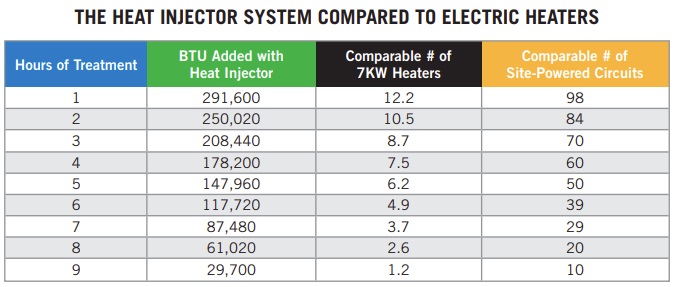

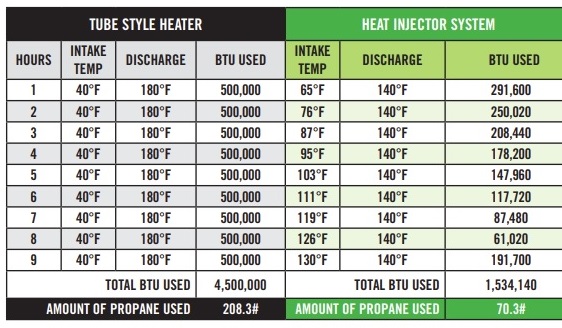

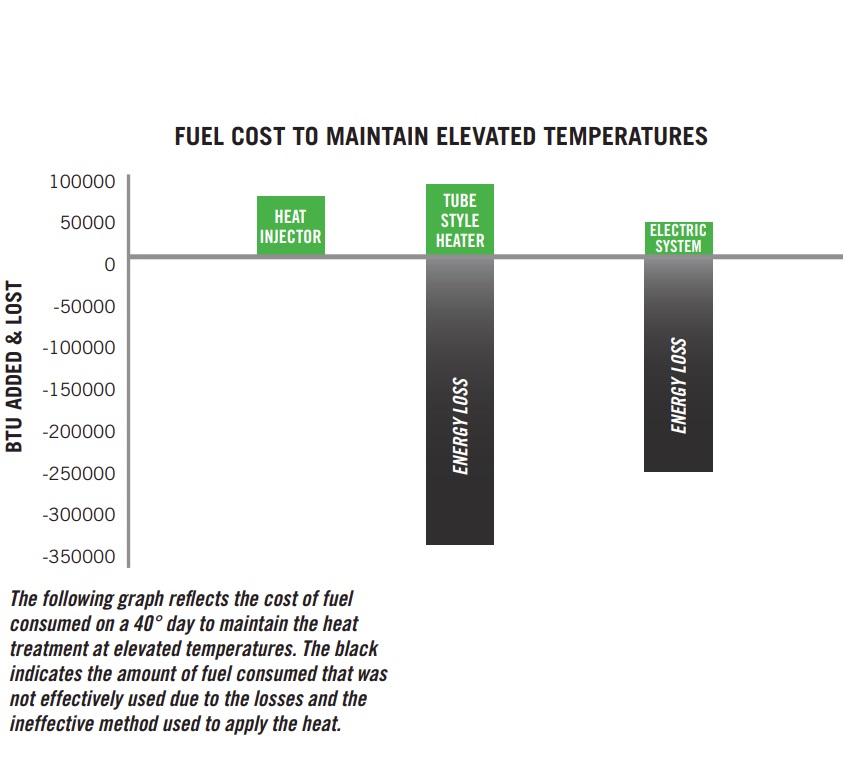

The Heat Injector System puts more heat into a heat treatment than the largest electrical system or the tube style heaters that consume significantly more fuel. The discharge temperature is adjustable from the Control Panel, with a range up to 160°F. The industrial blower with the HP Boost™ feature automatically compensates for load changes with different configurations of flexible duct attached to the discharge. When the load changes, the HP Boost automatically adjusts the motor’s speed to use all the power available from a standard 15 amp circuit to maximize the volume of air for every heat treatment.

Recirculated Airflow

The Heat Injector System utilizes a dedicated combustion blower to supply a small amount of fresh air, specifically for combustion (75 cfm).

With this patented concept, the air volume within the heat treatment can be recirculated to effectively apply the heat. This unique feature, along with the power of an industrial blower, allows the heated airflow to be recirculated through the heat treatment area. The heated airflow is discharged through a flexible duct to locations within the structure farthest from the Air Intake. The Air Intake draws air from the heated environment which creates an airflow through the space

With this patented concept, the air volume within the heat treatment can be recirculated to effectively apply the heat. This unique feature, along with the power of an industrial blower, allows the heated airflow to be recirculated through the heat treatment area. The heated airflow is discharged through a flexible duct to locations within the structure farthest from the Air Intake. The Air Intake draws air from the heated environment which creates an airflow through the space

Safe

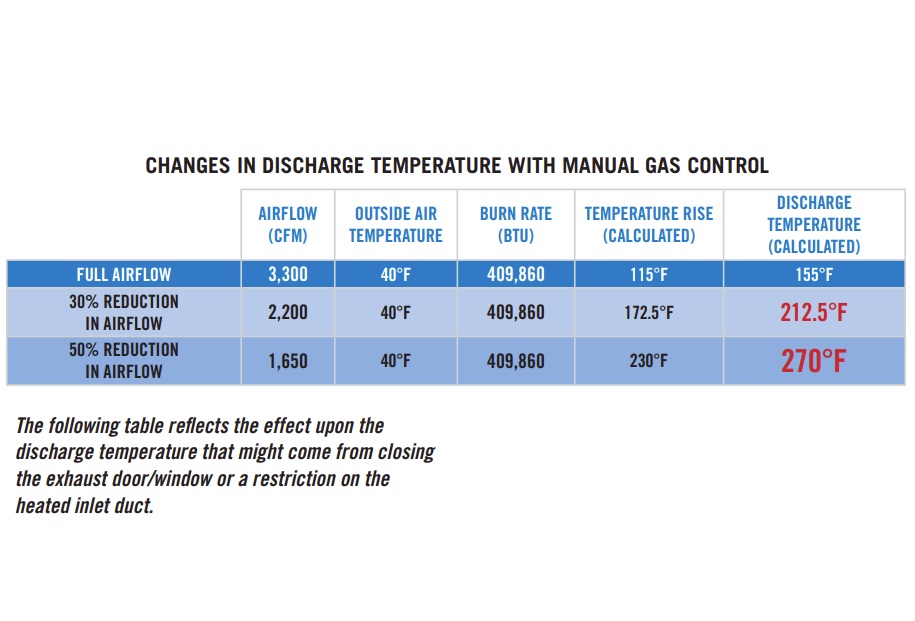

The Heat Injector plugs into any standard home outlet. The electrical controls are UL Listed. The on-board Temperature Control System is

critical to the safe operation of the Heat Injector. The discharge temperature is continuously monitored and the gas control is automatically modulated to achieve the desired discharge temperature. The desired temperature is maintained even when the airflow is manually adjusted or becomes restricted during the heat treatment

critical to the safe operation of the Heat Injector. The discharge temperature is continuously monitored and the gas control is automatically modulated to achieve the desired discharge temperature. The desired temperature is maintained even when the airflow is manually adjusted or becomes restricted during the heat treatment

The traditional gas-fired heaters manually modulate the gas to control the discharge temperature. If the airflow is reduced for some reason, the temperature can spike to hazardous levels.

Simple

With the Heat Injector – There are no need for generators, boilers, circulating pumps, special electrical hookups. A switch enables the airflow, another switch enables the heat, and then it operates automatically. Temperature sensors on the Air Intake and Discharge continuously monitor the heated airflow and display it on the Control Panel. The Air Intake temperature reflects the level of heat that has not been absorbed by the structure and its contents.

The Heat Injector is also designed for long life with low maintenance. The foam-filled tires, automatic overload protection, and automatic resets ensure reliable performance. The Modular design allows the belt to be tightened and makes access for repairs easy

Effective

The Heat Injector uses a unique method to thoroughly heat the structure and its contents. When the temperature is above the lethal temperature for bed bugs, the pressurization process is engaged to force heated air through electrical sockets and any openings in the structure. The pressurization process is typically done for the last hour of the heat treatment, but can be done longer given the specific situation, to ensure a successful heat treatment. The Heat Injector is transitioned to the Pressurization Mode by pulling a red knob to open an internal door to access air from outside the heat treatment. The volume of pressurization air is controlled by the engagement of the Modulated Air Damper. As the damper restricts recirculated airflow, more air is drawn from outside the heat treatment.

Discreet Heat Treatment

The Heat Injector System is positioned within an outside doorway or can be placed inside the heated environment with the use of the Air Shell. There is no generator or external duct which would draw attention to your client. The Heat Injector was designed to be moved to where the heat is needed with a single gas hose that connects to the Gas Manifold. The propane tanks can be moved close to the heat treatment. The hoses are typically 25 to 100 feet but can be up to 400 feet.