The Heat Injector Goes to Where the Heat’s Needed

Schedule a Chat!

Houses

Treats homes that are 3,500sq ft or larger

Apartments

The Heat Injector is able service up to 40 stories tall

Commercial

Customers have treated spaces as large as 35,000sq ft

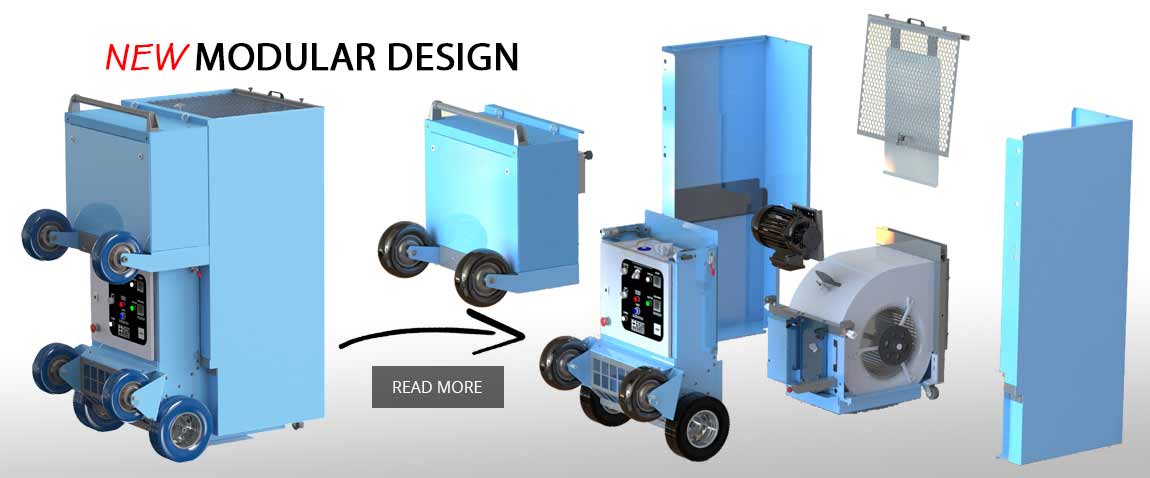

- Move the Heat Injector to the location of the bed bug infestation.

- Plug the Heat Injector into any standard outlet

- Attach flexible duct to the discharge of the Heat Injector with fabric connectors and run the discharge ductwork to transfer the heat into the remote locations

- Attach the gas hose to the Heat Injector using the quick disconnect (QD) fittings

- Turn on the Airflow switch and the Heat switch, set the desired discharge temperature, and adjust the airflow to maximum

- After the heat has been started, install doorway drapes to manage the airflow leaving the rooms

- At this point, it’s automatic; the heated airflow will continue to be pushed into the infested areas with the heat migrating toward the Heat Injector

- Place sensors in the heated area and monitor them to ensure all areas are thoroughly heated.

- During the periodic inspections, manage the heated airflow by moving the flexible duct to different discharge locations.

- When the Air Intake exceeds about 125°F, begin the pressurization process to force heated air through cracks and openings within the structure where bed bugs might find harborage.

Grow YOUR Business with the HEAT INJECTOR

Some of Our Clients

Testimonials

CMS